We’ve just been invited to run a bamboo building workshop in Davao, Philippines — about an hour outside the city — working with local tribal communities to build a structure similar to our main building in Belega.

I’m genuinely over the moon about this one.

As many of you know, returning to the Philippines has been a long-held dream of mine. For the past eight years I’ve been deep in it here in Bali — learning from master craftsmen, refining treatment methods, building community programs that try to blend real skill development with enterprise. So getting this invitation feels like everything is coming around in a full circle.

The goal of the workshop isn’t just to put up a building. It’s to help seed a small ecotourism enterprise — something that can generate local income, build genuine pride in traditional materials, and create lasting opportunity rooted in regenerative practice.

It Goes Both Ways

One of the things I’m most excited about is what I’ll be learning from our Filipino partner organisation, Evergreen Kawayan. They’ve shown me via video how they run their Boucherie treatment setup, and honestly I was impressed. The rubber hose fittings they use to pressurise the borax solution through the culms looked really practical — one of those elegantly simple solutions that strips out all the fiddly bits.

For the uninitiated, the Boucherie (or modified Boucherie) method works by pushing a pressurised preservative solution — typically borax and boric acid — through the vascular bundles of freshly cut bamboo, displacing the sap and replacing it with a preservative. Done well, it’s one of the most thorough treatment methods available, and it’s what gives bamboo the longevity it needs to compete structurally with conventional materials. Without treatment, you’re looking at three years before the bugs move in. With it, you’re building for decades.

These kinds of exchanges are exactly why I love this work. It’s never one-directional.

Over the past few months I’ve also been having a lot of conversations with people setting up bamboo production enterprises, and the more I think about it, the more clearly I see the case for cooperative-scale infrastructure.

I recall large industrial steam pressure chambers — the kind used for treating bamboo at scale run at around $100,000, which is no small number. But this is where cooperative models start to make enormous sense. Shared ownership. Shared processing. Shared benefit.

If you’ve followed Willie Smits, you’ll know he’s been pushing this thinking for a long time — centralised processing as part of a broader regenerative economic model. His work on the sugar palm in Borneo is a brilliant example: a processing facility in Tomohon that employs thousands of local tappers, paying above minimum wage, built around a crop that requires a healthy forest to thrive. The plant can’t be farmed in rows — it needs the complexity of a real ecosystem. So protecting the forest becomes economically rational, not just morally right. If you haven’t seen his talks or heard of the Masarang Foundation, it’s worth your time.

And the same logic applies to bamboo. If we want it to genuinely compete with steel and concrete, treatment at scale matters.

Village Level vs Enterprise Level

That said, I also deeply value the low-cost, village-level treatment methods I’ve been exploring with Jaye Irving. These approaches are vital in areas with no access to industrial infrastructure. They make self-sufficiency possible immediately. They don’t require big bucks and a cooperative agreement before a community can start protecting and using their material.

Both things are true. Both things are needed.

This tension is also feeding back into our Bamboo4Africa program. We’ve reopened discussions for this year’s training, working toward next year’s build at Nyakio’s place in Naivasha, Kenya — which Jaye will help develop across our upcoming three-month program.

The dots are connecting.

The Davao Build — March 10 – 19

So, back to the Philippines.

Here’s what we’re working with:

- 15 local participants

- 3 bamboo staff (Made will be on site)

- 5 international spots available

The training runs for 10 days starting March 10th.

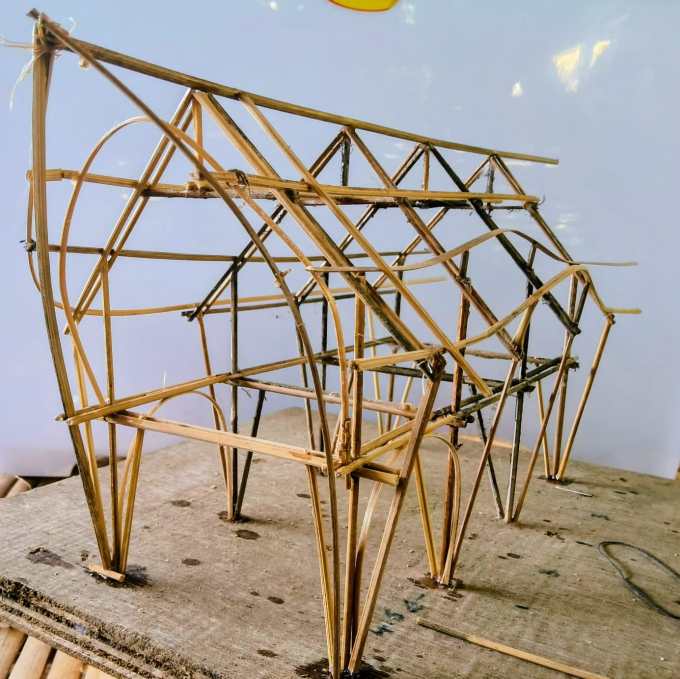

This is hands-on and straight into the build. Foundations will already be in place — we’re going straight to structure, joinery, and assembly.

If you’ve completed our 3-week program and want to come out and volunteer, get in touch.

If you know someone who’d love a real community bamboo build — not a workshop, not a demo, but actual construction — send them this way.

This isn’t theory. It’s building. Together.

I’ll be sharing how it all unfolds.

🌿

Discover more from Bamboo Creative Bali

Subscribe to get the latest posts sent to your email.